Blast window sourcing and installation represent a unique set of challenges to building managers. Not only are these windows very expensive and disruptive to install, there are a limited number of blast window manufacturers so the design selection is limited. Thermolite has been providing blast mitigation glazing retrofits to all government agencies for years and has, (what we believe is) by far the best permanent blast window solution for both existing buildings and new construction.

In addition to blast windows, there is one other method for protecting against the pressure and impulse of a blast event, which is to apply blast film to the existing window. Most of the installations of blast film that Thermolite has seen (over 95%) do not use a balanced design approach, which is mandated by GSA and ISC codes. A balanced design approach means that the glass must be held into the window, the window into the wall, and the wall to support the entire assembly.

In most cases, blast film is not attached to the window using structural silicone or a mechanical fastener. Instead, it is simply put on the glass which is not an acceptable blast design. What complicates the film installation is that the adhesive deteriorates after about 10-15 years. Afterwards, it doesn’t onto the glass the way it was originally designed. In fact, due it its expiration, the DOD initiative UFC 40-010-01 has prohibited the use of blast film on any DOD buildings. Instead, the DOD specifies laminated glass as the material of choice for blast windows.

Installing blast windows that utilize laminated glass has its own set of the challenges. One of the most challenging is that most blast windows require structural steel to secure the glass window into the window opening. Since this material doesn’t flex like the film, it transfers most of the load into the window jambs more quickly. However, this requires steel beams to be secured inside the wall, floor and ceiling to create a balanced design. If it wasn’t, the entire lite of glass would be blown out of the opening in the event of a blast explosion and fly into the room at a high rate of speed.

The problem with blast windows that require structural steel is that it is both expensive and intrusive to install. It’s impossible to install structural steel without disrupting tenants. This makes a blast window project very difficult for the contracting officer to source since many general contractors have little experience with this type of product.

Blast windows have limited design options. Architects are often forced to choose a blast window that may not be their preferred style or aesthetic. One example of this is a historic building that has wood windows. Assuming that these could be replaced in the first place, do you really want to place steel or aluminum windows in a historic building that once had wood windows? Perhaps there is a color or shape of the window that is not available in the limited supply of blast window designs.

Thermolite’s blast window system is the only one available on the market that eliminates all of these challenges. First and foremost, Thermolite blast windows don’t require structural steel in it’s design. Our windows utilize a patented compression release technology, which uses a flexible perimeter that reduces the total load transferred to the perimeter anchorage and existing window frame.

Thermolite blast windows install on the interior of the existing window, and are specifically designed to absorb the pressure of the exterior window and prevent glass from entering the room. In doing so, Thermolite blast windows are one of the only viable blast applications for historic buildings since there is no alteration to the exterior window, frame or wall, meeting all historic preservation guidelines. In addition, since Thermolite blast windows install on the interior of the building, there is virtually no limitation of the design of the exterior window.

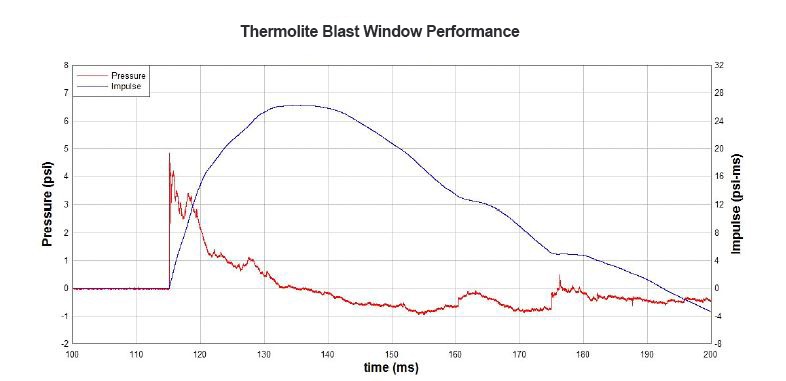

Thermolite works well with high explosives at short distances with smaller impulses. Our windows have successfully been tested at 10psi and 90 psi*ms although most applications are much lower than this.

The test graph below shows the actual load cells on the window during a blast test which passes at a lever 2 which means only glass dust was noticed in the test chamber. This was an open air blast test with 500 lbs of ANFO at 190 feet.

The Thermolite Blast Window Methodology:

(For new or replacement blast window projects with fixed windows and pressure up to 10 psi and 90 psims)

- Select any window from any manufacturer as your exterior window. This is just like selecting a new window based on energy performance, aesthetics, color and cost.

- Eliminate all of the steel in the opening if designed for a blast window. Only masonry is required for the Thermolite epoxy anchors.

- Provide Thermolite with a cut section of the existing window to be placed on the exterior.

- Thermolite will provide a Thermal Analysis of the improved window and detail the anchoring location around the window opening.

- A blast analysis will be provided which will detail and support all of the anchoring locations to the design pressure.

One construction begins, coordinate your window glazier as you would for any other simple window replacement or installation project. Thermolite will be able to install our interior blast windows right behind the exterior window while installers work.

The end result will be a blast window that will have the desired look, will be installed faster and is much less expensive than a replacement blast window. Contact us today to learn more about Thermolite blast windows.